VMR-FR3300L

In January 2022, Lanxin Technology introduced a vision SLAM unmanned forklift, followed by the launch of the first CE-certified handling robot product LXCE-FR3600L in April 2022. Just under a month later, on May 24, Lanxin Technology officially released the Intelligent Loading System, which has already been successfully implemented in the chemical industry, receiving positive feedback from customers.

Seizing Opportunities in Demand

Lanxin Technology's entry into the market with vision-based mobile robots is unique in the industry. As a robot enterprise with deep expertise in developing its own mobile robot deep vision system and achieving mass application, Lanxin Technology stands out among numerous AGV/AMR companies.

Why did this "mobile robot company" choose to enter what seems like a cross-industry field? According to Gao Gong Robotics, this decision may be attributed to the massive demand in loading scenarios and the core technology LX-MRDVS (robot deep vision system) developed by Lanxin Technology.

The loading process is a crucial link connecting in-factory logistics with external logistics in the manufacturing industry. Traditionally, loading processes have relied heavily on manual labor, resulting in time-consuming procedures and errors in load quantity. In industries such as fertilizers with substantial shipment volumes, these issues become particularly prominent.

Statistics show that from 2015 to 2021, global fertilizer demand has consistently exceeded 190 million tons, with the total fertilizer consumption in 2021 reaching 203.8 million tons. This translates to a staggering number of loading and unloading operations in the fertilizer industry annually. However, despite this immense demand, many companies in the industry still employ traditional manual methods for loading and unloading.

The reason behind this is not a reluctance to seek more intelligent solutions; rather, there is a lack of automated loading and unloading solutions tailored for bagged fertilizers in the market.

With nearly two decades of experience in the field of deep vision, Lanxin Technology saw a tremendous market demand and business opportunity. Backed by market demand and technological support, the company's transition from "mobile robots" to "loading robots" might not seem so surprising.

Lanxin Technology Intelligent Loading System Hits the Market

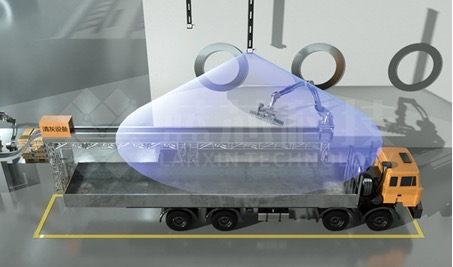

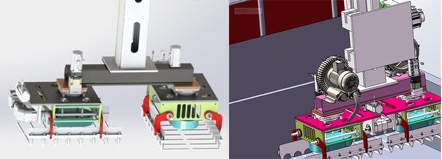

The Lanxin Technology "Intelligent Loading System" revolves around 3D vision sensors, robotic arms, mobile robots, and a central control system. It effectively connects various independent operational processes, addressing several challenges in the loading process. In terms of end results, the system achieves unmanned and autonomous handling of loading units, intelligent recognition of vehicles, automatic calculation and planning of storage locations, and automatic stacking of goods, among other complex operations.

Taking the example of the intelligent loading solution developed by Lanxin Technology for Z Group, a major chemical raw material producer with an annual capacity of nearly 300,000 tons, the company faced challenges with manual loading, including time-consuming processes, potential errors in loading quantity, high labor intensity, and difficulties in recruiting workers. After careful consideration, Z Group chose to implement Lanxin Technology's "Intelligent Loading System."

Throughout the project's development, various challenges were overcome. For instance, in addressing the issue of soft packaging recognition, the typical method for robotic arms to secure soft packages is by selecting the package's center of mass to ensure stability during gripping. However, Z Group's packages often presented a different challenge with masses and geometric centers misaligned and spaced apart. Lanxin Technology utilized its self-developed 3D vision sensor and data recognition algorithm to continuously learn and correct, achieving accurate recognition of the center of mass and significantly improving gripping stability.

The Lanxin Technology "Intelligent Loading System" boasts several key advantages:

1. Substantial Improvement in Loading/Unloading Efficiency:

- Single robotic arm: 1000 bags/hour

- Dual robotic arms: 1600 bags/hour

- Payload per bag: 25-50 kg

- Example: Loading a 30-ton truck with 50 kg/bag of fertilizer takes only 0.6 or 0.375 hours using the Lanxin Technology system, compared to approximately 2 hours with manual loading.

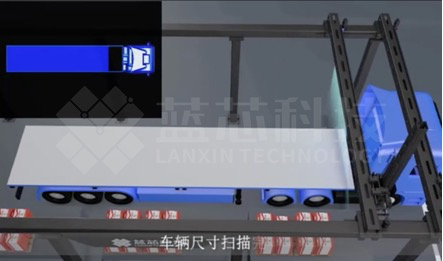

2. Automatic Vehicle Scanning Imaging:

- The system continuously scans and extracts vehicle features, automatically detecting and comparing vehicle specifications, including length, width, and height.

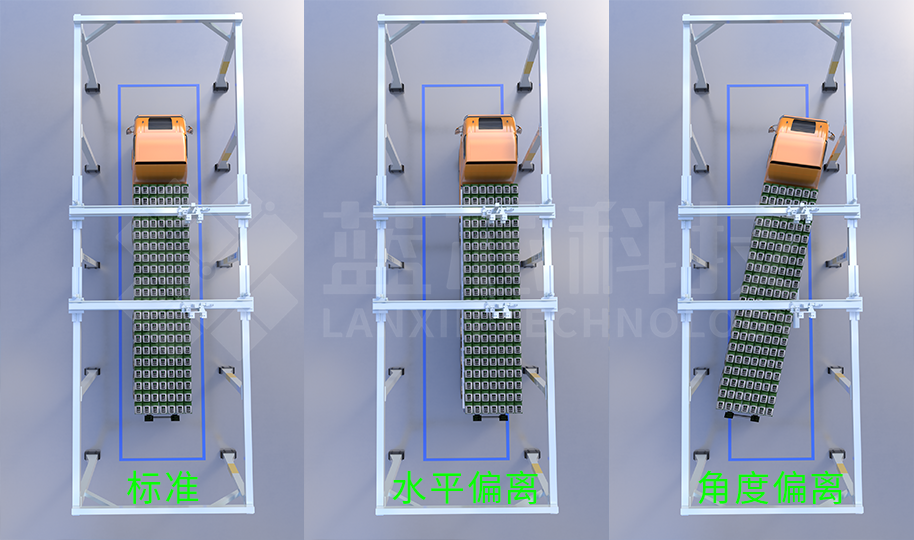

3. Intelligent Vehicle Deviation Correction Algorithm:

- Automatically corrects horizontal deviations and angle stops when the vehicle experiences deviations, compensating for parking discrepancies.

4. Flexible Stacking Algorithm:

- Based on Lanxin Technology's self-developed 3D vision sensor and stacking algorithm, the system achieves automatic stacking of bags in horizontal and vertical orientations, effectively increasing the utilization of cargo space.

5. Independent of On-Site Air Source:

- The robotic arm uses a vacuum pump suction device that does not rely on on-site air sources. It is lightweight, flexible, low in friction, and has a long service life with low energy consumption.

6. Adaptable to Various Vehicle Models:

- The free-falling robotic arm can adapt to different truck models, including flatbed trucks, low-deck trucks, and high-deck trucks, ensuring efficient and swift loading.

CEO of Lanxin Technology, Gao Yong, stated, "The Intelligent Loading System is a significant project for the company. From research and development, project initiation, testing, to achieving the expected results, the project took over 500 days and overcame more than 100 challenges. In addition to significantly improving loading efficiency for enterprises, the Intelligent Loading System also effectively addresses longstanding issues such as labor shortages, work-related injury risks, and occupational diseases."

Expanding the Boundaries of the Deep Vision Market

The introduction of the "Intelligent Loading System" by Lanxin Technology signifies the potential expansion of its core technology, LX-MRDVS, from mobile robots into general industrial applications.

Since its establishment in 2016, Lanxin Technology's comprehensive products and solutions based on its self-developed LX-MRDVS have covered a wide range of industries, including 3C, semiconductors, PCBs, new energy, automobiles, packaging, railway chemicals, pharmaceuticals, and construction machinery. The company has provided services to well-known enterprises such as Huawei, ZTE, Midea, Toshiba, Foxconn, Hailishi, Xinxing Electronics, Toyota, and other leading companies in industries like photovoltaics and lithium batteries.

CEO Gao Yong of Lanxin Technology mentioned, "By adopting LX-MRDVS in different ways, we can break through more complex application scenarios, including but not limited to production line logistics, loading/unloading vehicles. In the future, Lanxin Technology will continue to expand the market boundaries of LX-MRDVS, supporting more enterprises in their transition to intelligent, digital, and upgraded operations."

Contact Us

Lanxin Technology, 7-802,

China Artificial Intelligence Town,

No.1818-2 Wenyi West Road,

Hangzhou, Zhejiang, China

marketing@lanxincn.com

Popular Products

Cases

Industry